SVX Optics

Stellarvue's optics have evolved over the past 25 years with the addition of advanced testing equipment. Here is how we currently produce our SVX objectives.

Stellarvue's optics have evolved over the past 25 years with the addition of advanced testing equipment. Here is how we currently produce our SVX objectives.

Measuring Accuracy: The accuracy of an astronomical optic may be expressed in terms of Strehl ratio, introduced by the German physicist, Dr. Karl Strehl. A theoretically perfect lens would have a Strehl ratio of 1.0 so under this system of measurement, optics are rated using a fraction of the number 1. An objective with a Strehl ratio of .95 is much more accurate than one that measures .90. As this fraction declines you will see more and more issues in the objective that impact performance.

The Process: Lens designs are developed to meet our requirements both in terms of visual use and in imaging with CCD or CMOS cameras. We use super low dispersion glass for the best color correction and contrast. For more information on glass visit our page on Glass Types.

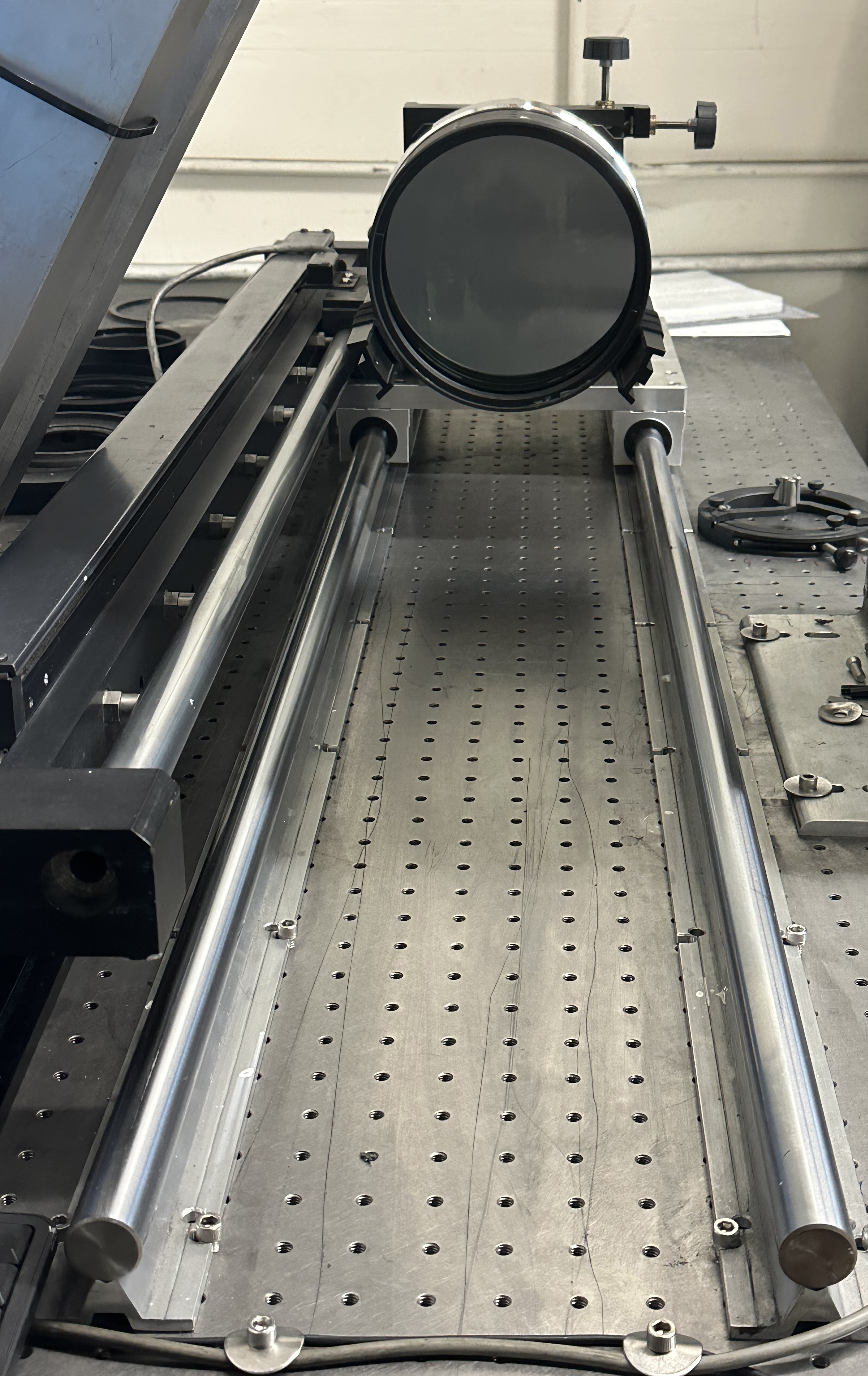

Glass is ground and polished to meet our prescription. Once this is accomplished, we utilize our Zygo Phase Shifting Laser Interferometer (shown to the left) to carefully figure each objective to eliminate common issues we find in machine polished objectives. These include astigmatism, coma, and spherical error. We also address trefoil by replacing any elements that exhibit this aberration during the process.

Optical figuring to improve performance is accomplished in two stages:

Stage one: Reducing optical aberrations that impact performance (astigmatism, coma, spherical error) to the lowest level possible.

Stage two: Making the final spherical correction.

Figuring - Stage One

In stage one we reduce aberrations. To understand how this is done, let’s look at one of these aberrations:

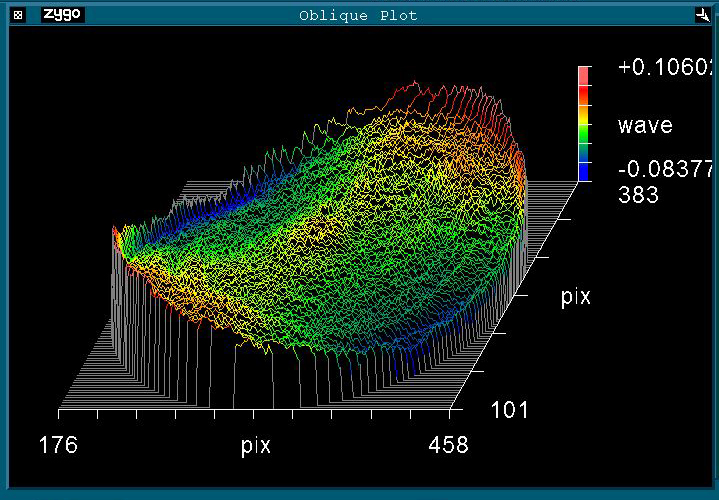

On-axis astigmatism happens when a lens (or its wavefront) is asymmetrical after being polished. This may make the optical wavefront look like a potato chip as seen to the left. Since the wavefront is not symmetrical, the focal length will vary as we move from one location to another within the circumference of the lens. Light from one plane comes to focus at a different location than light from another plane. This will turn a point of light (a star) into a distorted line or a cross.

This is an oblique plot taken using our Zygo showing a greatly magnified view of a wavefront from an objective assembled after machine polishing. These high and low areas are greatly exaggerated so they become obvious. See how misshapen the wavefront appears on this particular objective? Ideally, this wavefront should be more even but in this view the characteristic "potato chip" appearance is obvious. To fix this, we first rotate elements to improve symmetry, then we work the glass to further reduce on-axis astigmatism to an extremely low level. At this stage the master optician improves the wavefront by making it more symmetrical. During this lengthy process, we reduce astigmatism through dozens and dozens of individual figuring sessions.

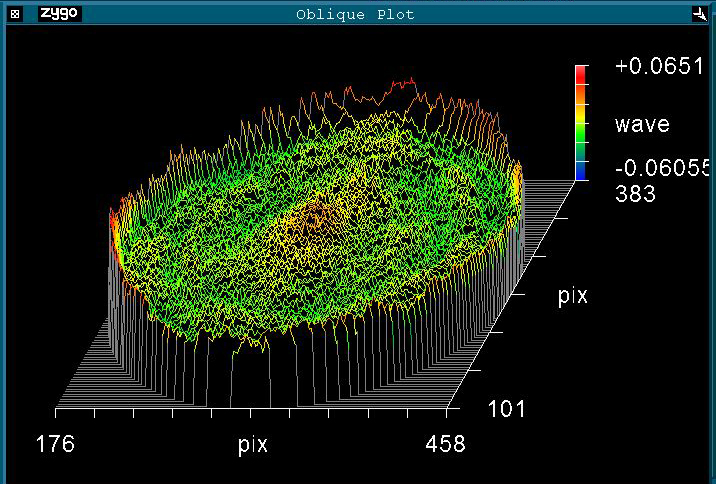

This work is extremely meticulous. Each time a rub is done, the lens must be cleaned, cooled overnight, reassembled, and re-aligned. Then the next measurement is taken showing how much more work is needed. This process is repeated dozens and dozens of times over until we reduce astigmatism to the lowest possible level. As astigmatism is brought under control, the accuracy increases and other aberrations that were hidden now begin to appear. Each one of these issues will be corrected in order to bring the objective lens up to the highest level of optical accuracy we can attain. The second oblique plot is the final test of the same objective shown above after months of hand figuring to reduce aberrations to the lowest possible level.

Final Figuring – Stage Two

In the summer of 2023, we implemented a minor change in our process as part of our continuous improvement efforts. We now perform additional figuring sessions to move the center of optical correction toward the middle of the visual spectrum.

In the summer of 2023, we implemented a minor change in our process as part of our continuous improvement efforts. We now perform additional figuring sessions to move the center of optical correction toward the middle of the visual spectrum.

If you are interested in purchasing a Stellarvue telescope and have questions, call us at (530) 823-7796 or email mail@stellarvue.com.