The Process

Lens designs are developed to meet our requirements, for both visual use and imaging with CCD or CMOS cameras. We use super-low dispersion glass for the best color correction and contrast. For more information on glass, visit our page on

Glass Types.

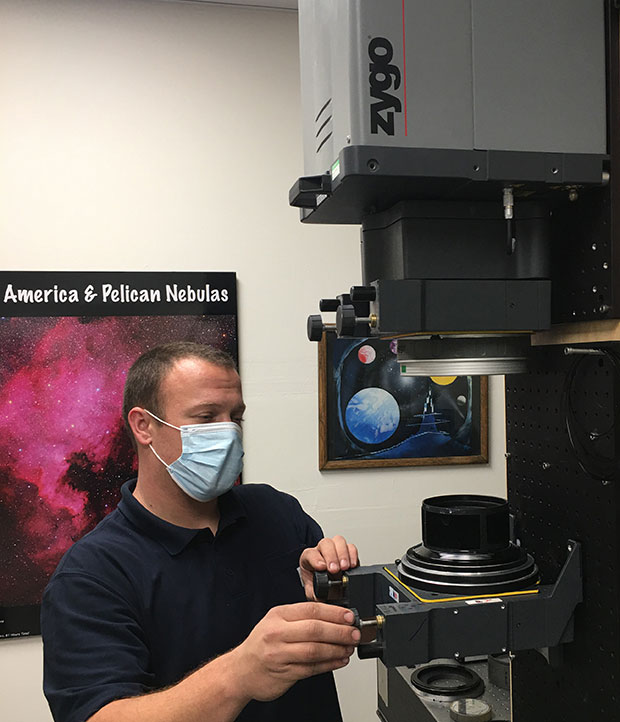

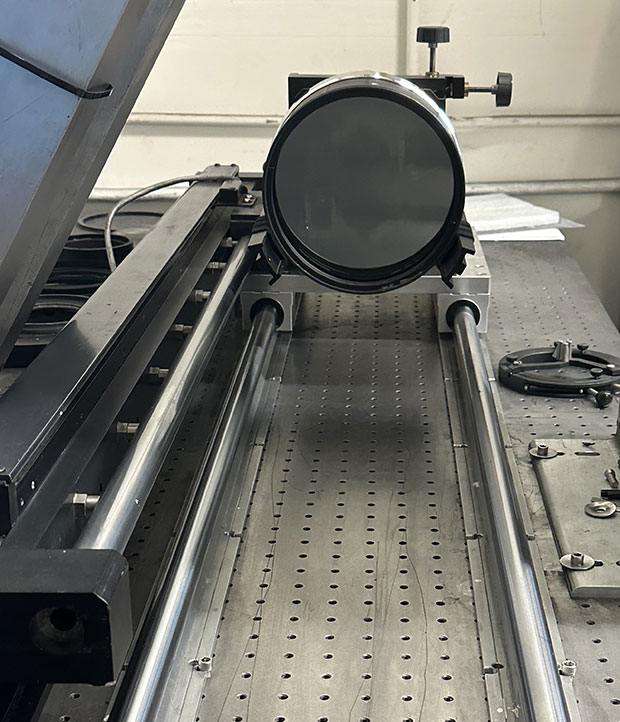

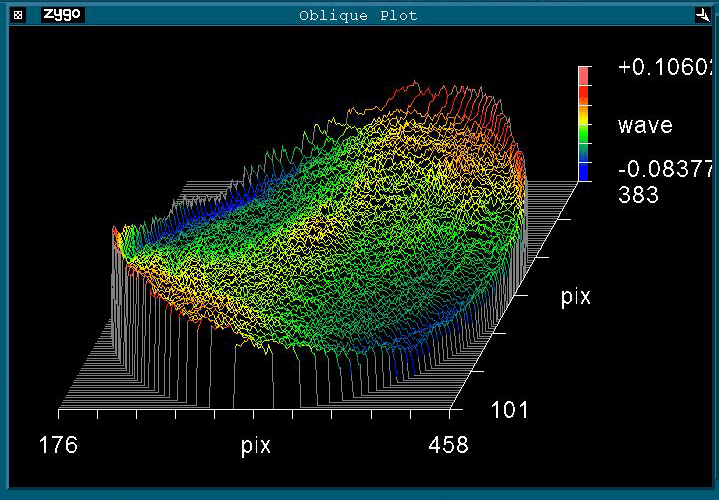

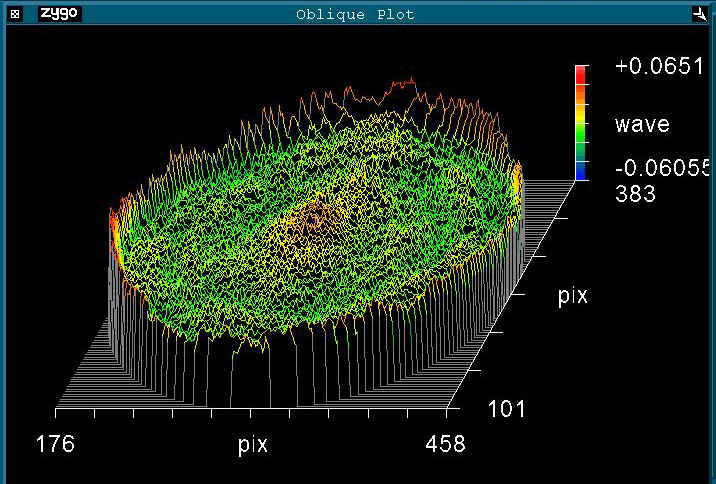

After glass is ground and polished, we use our Zygo Phase Shifting Laser Interferometer and our Double Pass Autocollimator to figure each objective carefully. This process eliminates common issues we find in machine-polished objectives, including astigmatism, coma, and spherical error. We also address trefoil by replacing any elements that exhibit this aberration during the process.

Optical figuring to improve performance is accomplished in two stages:

- Reducing optical aberrations that impact performance (astigmatism, coma, spherical error) to the lowest level possible.

- Making the final spherical correction.