Measuring Accuracy

The accuracy of an astronomical optic may be expressed in terms of Strehl ratio, named after the German physicist Dr. Karl Strehl. A theoretically perfect lens would have a Strehl ratio of 1.0, so under this system of measurement, optics are rated using a fraction of the number 1. An objective with a Strehl ratio of .95 is much more accurate than one that measures .90.

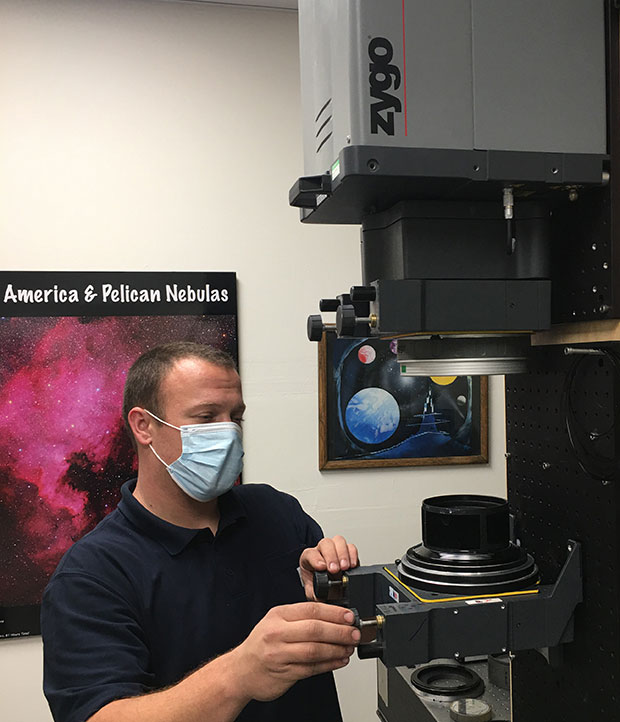

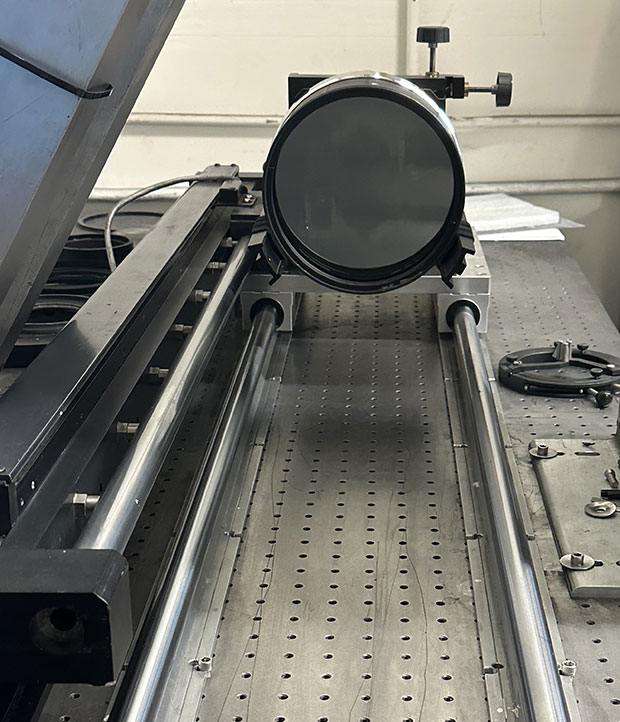

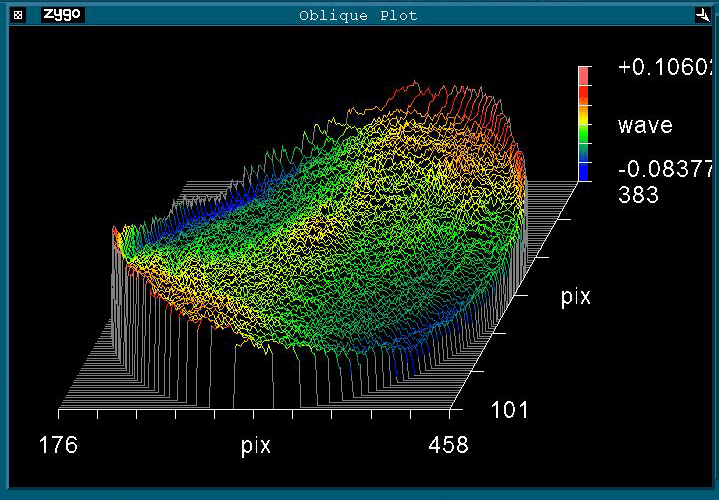

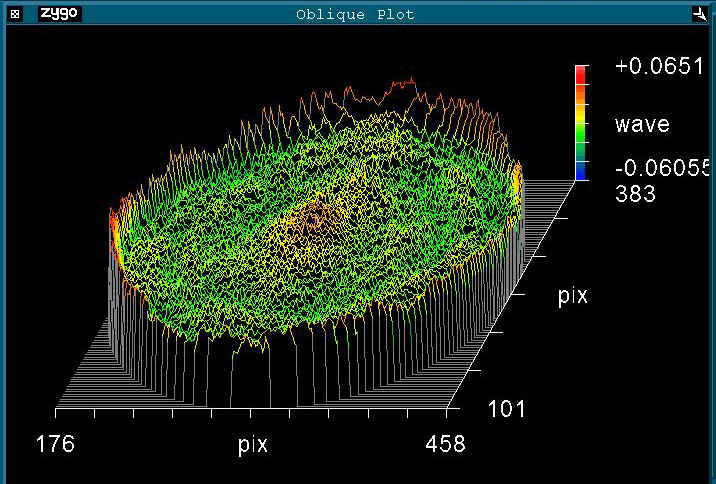

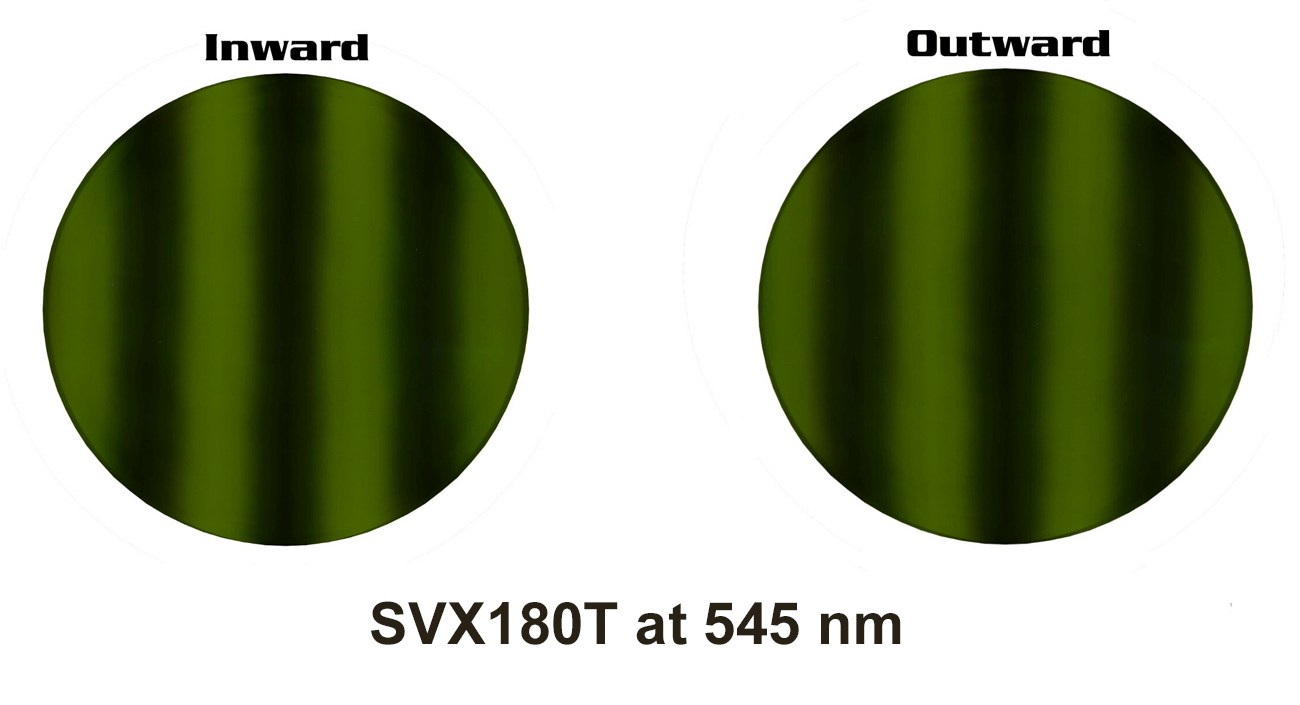

Strehl ratio is only one indicator of optical accuracy. We do not meticulously figure our objective lenses just to get a better Strehl number. Rather, we spend a great deal of time figuring the glass and testing the results on a daily basis to minimize aberrations. Our goal is to minimize aberrations below the theshold of detectability, improving the performance of the objective. A polished objective may have several aberrations and we use the Zygo interferometer to detect these. We map the optical wavefront, then we figure the glass to minimize these issues.

So the Zygo Interferometer is not used to simply show how accurate an optic is, it is a tool we use daily to improve the performance of our optics by minimizing aberrations.